Project overview

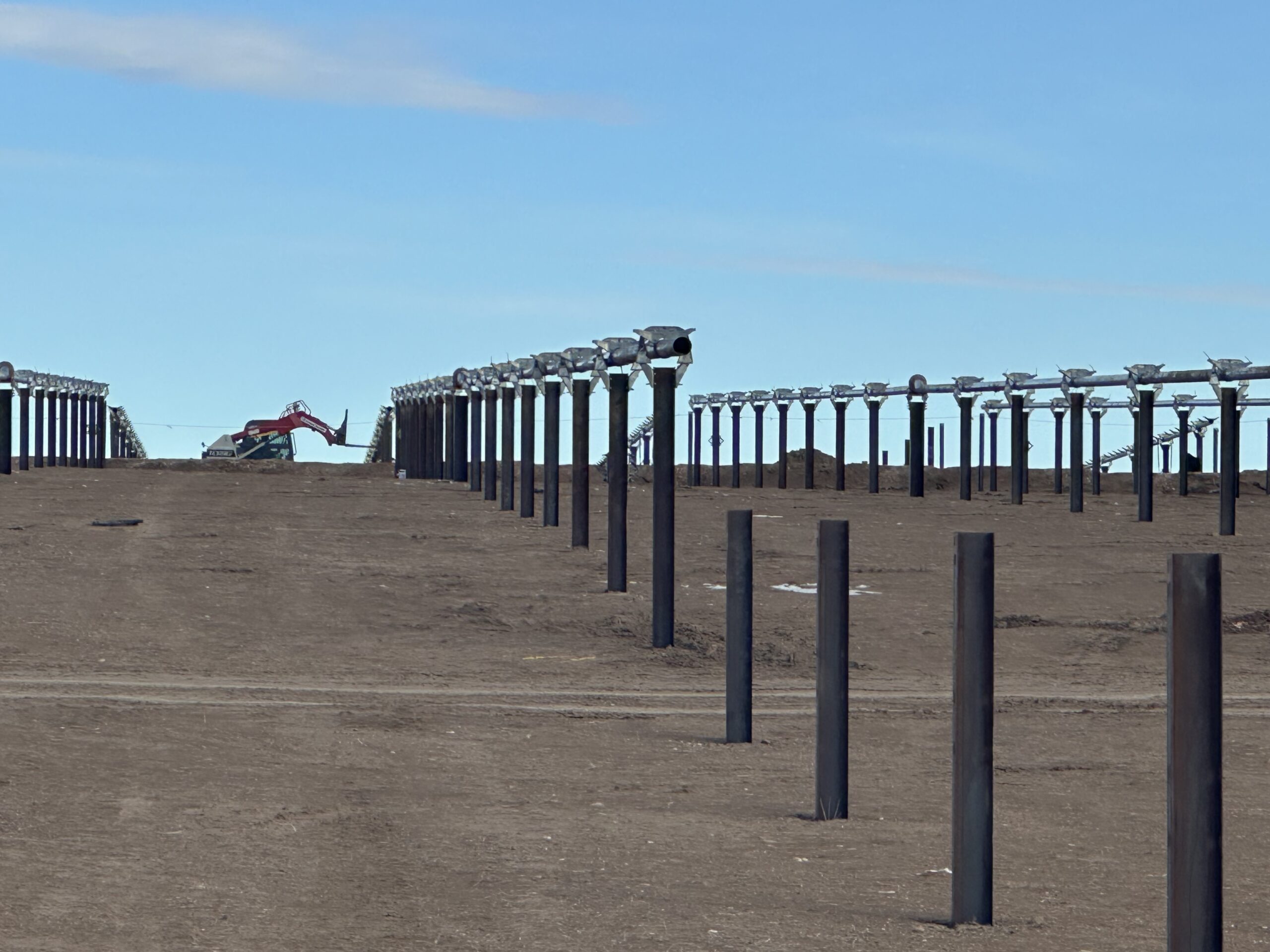

In January 2025, we announced the acquisition of Black Hollow Sun (BHS) Solar Complex in Colorado, constituted by 2 phases. BHS phase I, 185 MWp plant, that stared operations in October 2025, and BHS phase II, 139 MWp, which construction continues at a strong pace.

The expectation is to have the entire Black Hollow Sun complex fully operational by Q4 2026, providing energy to Platte River Power Authority, a community-owned public power generation and transmission utility, under a 20-22 year busbar Power Purchase Agreements (PPAs) grandfathered into the IRA tax credits . This new clean energy will be enough to power more than 73,000 residences and business in Fort Collins, Estes Park, Longmont, and Loveland annually.